Has Mercedes-Benz solved the battery challenge regarding electric vehicle batteries? It’s possible the luxury automaker has solved one of the biggest EV issues.

In addition to the concern regarding how EV batteries are built and where the materials come from, many environmentalists have expressed concern regarding the ability to recycle batteries. The EV market is still relatively new, and some people weren’t sure if the batteries would be capable of being recycled. It seems that Mercedes-Benz has figured this out and could move the global environmental needle forward and show the rest of the automotive world how to close the loop.

What is the loop?

In this case, the loop is the electric car battery and whether or not it can be recycled to create more batteries. If this loop can be closed, then old batteries can be created as new batteries. The same loop is basically closed in terms of traditional vehicles. Nearly every part of most cars can be recycled and reused to make new cars. Some cars go to junkyards and act as supply stations for used parts that owners can source and enjoy for fractions of the cost of new parts, while other vehicles are stripped down and recycled into metals that can be used again.

What has Mercedes-Benz done?

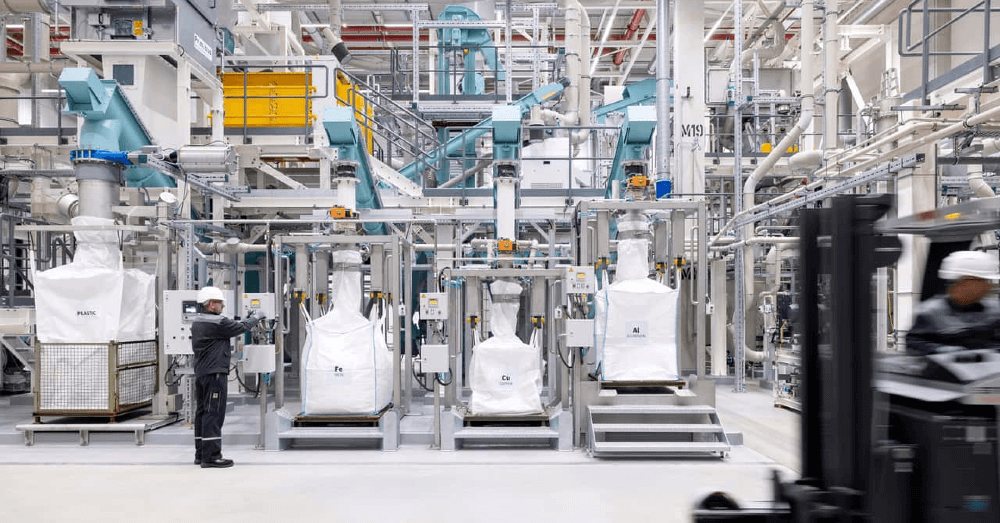

The very first battery recycling plant in Europe was opened by Mercedes-Benz. This plant is designed to recycle electric vehicle batteries, making it the first time a car manufacturer has built a facility to close the loop. The new battery recycling plant has an integrated mechanical-hydrometallurgical process to allow an electric vehicle battery to be recycled. Unlike established processes, the expected recovery rate of this new process is more than 96 percent from these batteries. This allows valuable and scarce raw materials to be recovered from the batteries. This means lithium, nickel, and cobalt can be reused in new batteries.

Sustainability is the key

The new plant at Kuppenheim, Baden in Germany is the biggest step for Mercedes-Benz to take in order to become fully sustainable. Most automakers are working toward a carbon-neutral process of building cars and batteries. A new EV battery recycling plant could easily be the right step forward to ensure the brand can be sustainable and continue to have processes that help protect the environment rather than harming it.

“Mercedes-Benz has set itself the goal of building the most desirable cars in a sustainable way. As a pioneer in automotive engineering, Europe’s first integrated mechanical-hydrometallurgical battery recycling factory marks a key milestone toward enhancing raw-materials sustainability. Together with our partners from industry and science, we are sending a strong signal of innovative strength for sustainable electric mobility and value creation in Germany and Europe.”

– Ola Kallenius, Chairman of the Board of Management of Mercedes-Benz Group AG

A partnership in recycling

The technology partner working with Mercedes-Benz in Eve battery recycling is Primobius. This joint venture between the new plant in Germany and SMS group and Neometals shows how these companies can work together to achieve a specific goal. The plant receives funding from the German Federal Ministry for Economic Affairs and Climate Action. This is part of a scientific research project with three German universities to look at the entire process of scaling the plant for the future of battery recycling in Germany.

Other plants need to open

The concerns over electric vehicle battery recycling are nothing new. Some companies have found ways to reuse these batteries in smaller electric vehicles or for home appliances. Some companies have worked to understand what percentage of these batteries can be recycled, but Mercedes-Benz is the first to make it happen. As the electric vehicle market continues to grow, more plants aimed at recycling the rare-earth metals from the batteries will be necessary to build new batteries. The goal is to minimize the need to mine these metals, which are limited in elemental quantities around the world.

How does the process work?

The mechanical process being used by Mercedes-Benz separates and sorts the plastics, coper, aluminum, and iron in a complex, multi-stage process. The active materials that make up the electrodes of the battery cells is separated further down the line, extracting cobalt, nickel, and lithium from the mixture using a multi-stage chemical process. The recycled materials are of battery quality and can be reused in the production of new battery cells.

With a 96% recycled rate, the new Mercedes-Benz EV battery recycling plant makes it easy for the brand to produce new batteries using most of the materials from old batteries. Will other automakers follow suit and build battery recycling plants? They certainly should.

This post may contain affiliate links. Meaning a commission is given should you decide to make a purchase through these links, at no cost to you. All products shown are researched and tested to give an accurate review for you.